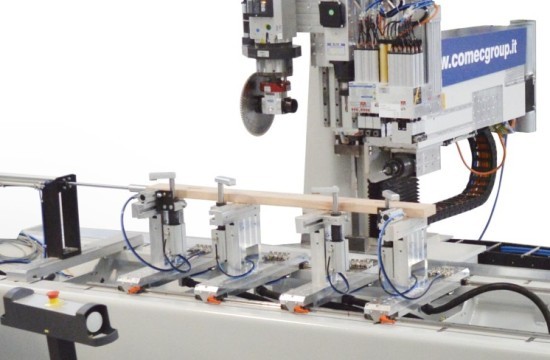

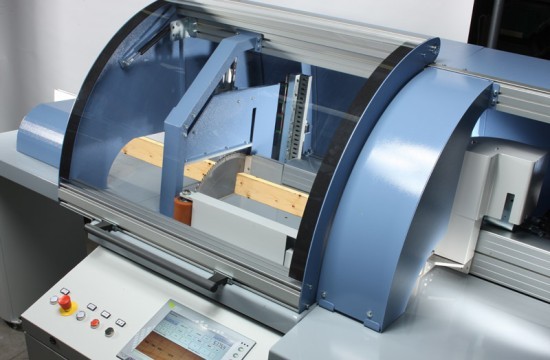

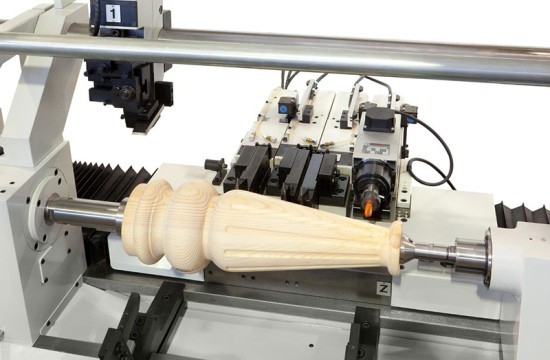

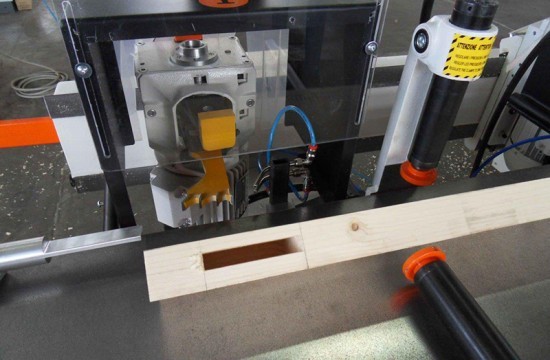

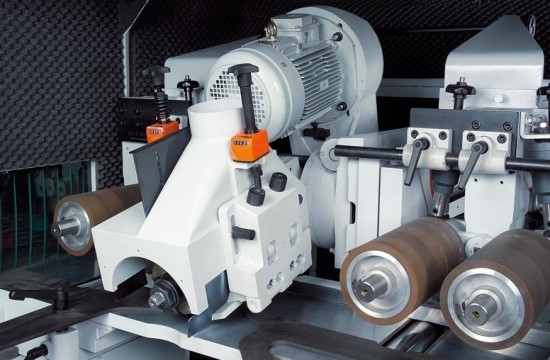

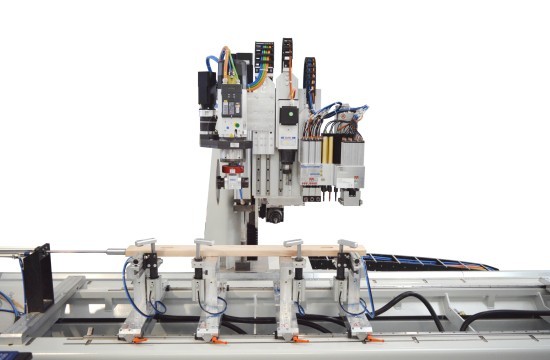

New CNC woodworking machinery including automatic crosscut saws, lathes, moulders and mortisers from leading brands.

Contact a specialist to discuss a tailored solution for your production requirements.

We can help you choose the correct equipment and specification to suit your production needs.

The website uses cookies.

Some are used for statistical purposes and others are set up by third party services. By clicking 'Accept all & close', you accept the use of cookies. For more information on how we use and manage cookies, please read our Cookie Policy.

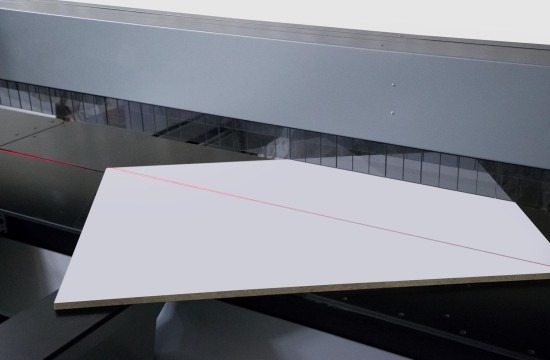

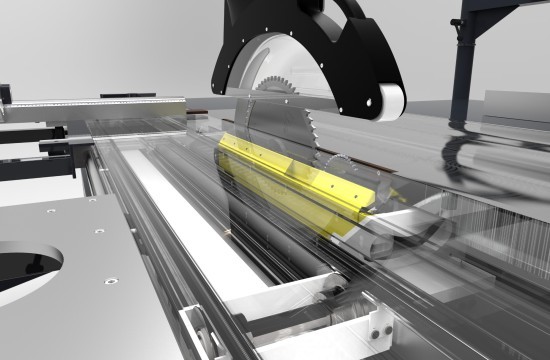

Boost productivity with the Fimal Concept 350 Beamsaw.

By bridging the gap between manual saws and traditional beamsaws, it offers superior accuracy, enhanced safety, and better efficiency with advanced board optimisation software.

Find out more