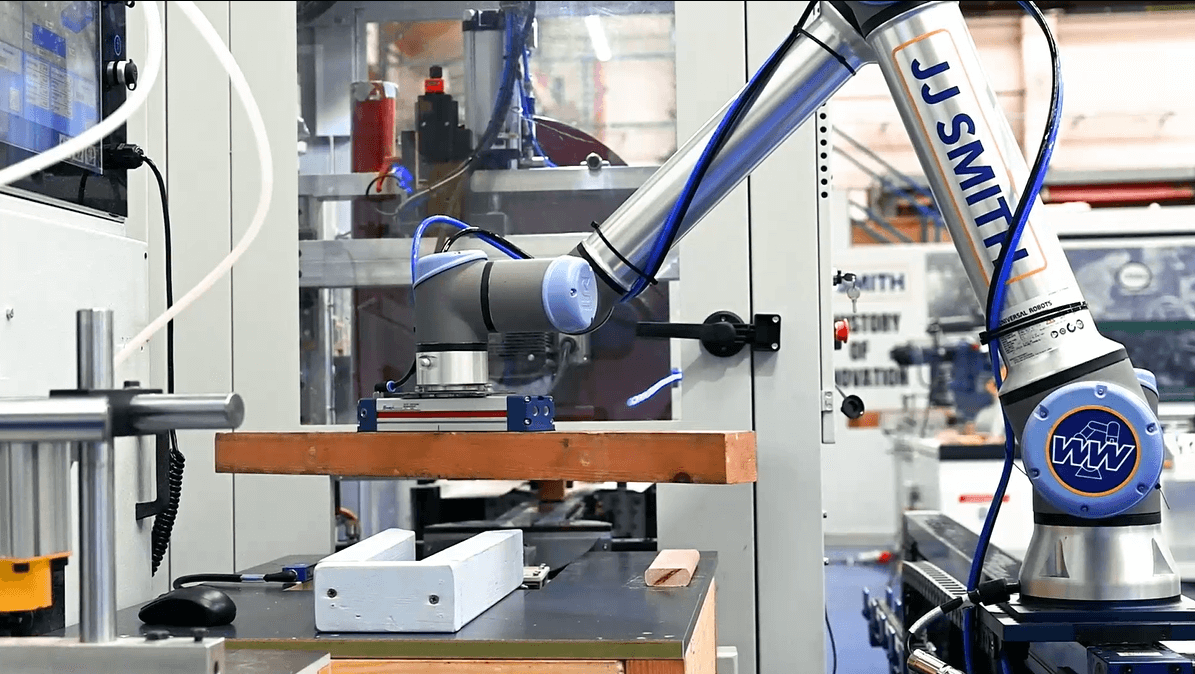

Automated Handling Solutions for Woodworking

Woodworking Robotics offer a wide range of automated handling applications to streamline your woodworking manufacturing production, including material handling, robotic and cartesian palletising, and loading and unloading machinery.

Improve workplace safety by allowing the woodworking cobots to handle dangerous tasks. The cobot is designed to work collaboratively with humans, with the intelligence to know if it has come into contact with a person and programming to operate in a reduced mode when a human enters the cobot’s workspace, resuming at full speed with the person leaves.