Looking to buy used/second hand woodworking machinery?

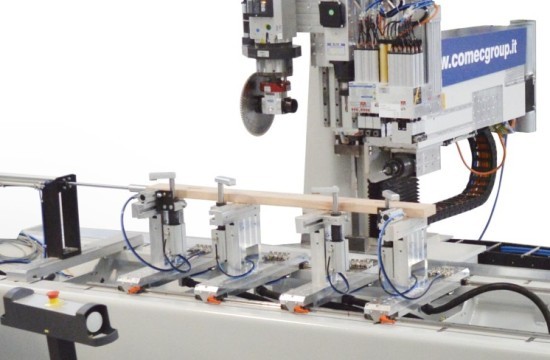

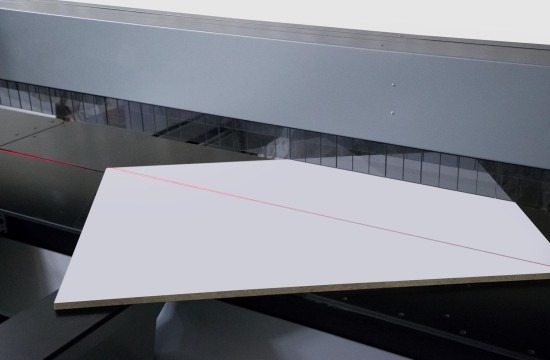

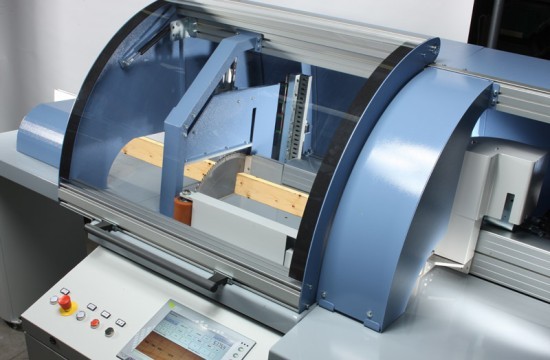

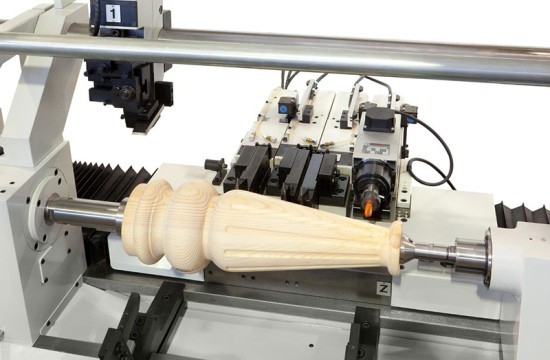

We offer a wide range of high quality second hand woodworking machinery including crosscut saws, lathes, mortisers and CNC machining centres.

Contact a specialist or arrange a visit to our showroom.

Aluminium, Plastics & Composites

Band Resaws

Bandsaws

Beamsaws

Boring & Drilling

Clamping

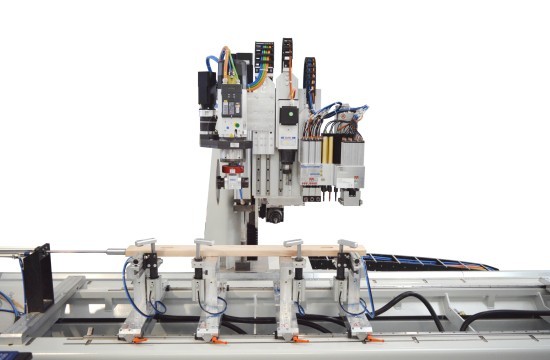

CNC Machining Centres / Routers

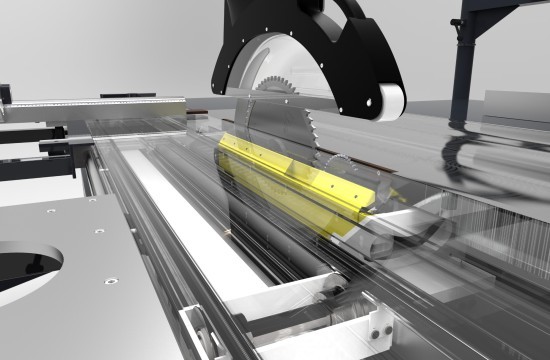

Crosscut Saws (Automatic)

Crosscut Saws (Manual)

Edge Bander

Finishing & Spraying

Glue Spreaders

Handling

Lathes

Miscellaneous

Mitre Saws

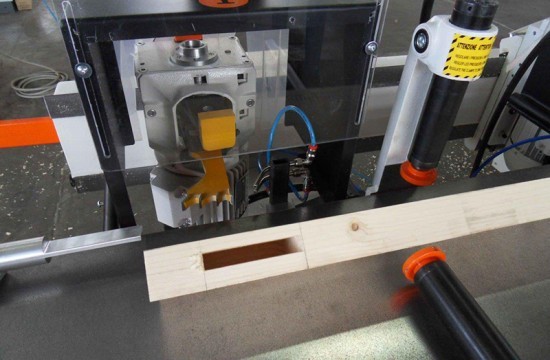

Mortisers

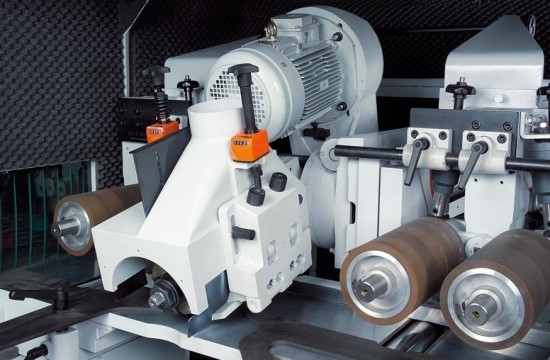

Moulders

Multi Rip Saws

Notching & Haunching

Panel & Ripsaws

Planers

Presses

Roller Tables & Stops

Routing & Shaping

Sanders

Specialist Applications

Spindle Moulders

Tenoners

Timber Frame & SIP

Waste Recycling & Extraction

We can help you choose the correct equipment and specification to suit your production needs.

The website uses cookies.

Some are used for statistical purposes and others are set up by third party services. By clicking 'Accept all & close', you accept the use of cookies. For more information on how we use and manage cookies, please read our Cookie Policy.

In stock and available to buy online with immediate delivery.

With a generous cutting capacity up to 170mm and unique pivoting saw unit, the Graule ZS170 is ideal for straight and angled cutting.

A great addition to your workshop for just £6,159 + VAT!

Find out more