A key upcut saw within Rowlinson’s production facility had reached the end of its service life and was beyond economic repair. This created the immediate risk of delays and bottlenecks across the cutting process. The company initially considered sourcing a second-hand saw as a short-term solution. However, given the importance of uninterrupted production, it was clear that any replacement would need to be delivered quickly and capable of meeting the long-term demands of a busy manufacturing environment.

Rowlinson turned to JJ Smith, their long-standing machinery partner, who were able to provide a far more effective solution. JJ Smith had in stock and available for immediate delivery the Stromab Matrix Automatic Crosscut Saw, a machine designed to combine the precision of fine joinery with the robustness required for high-volume sawmill production.

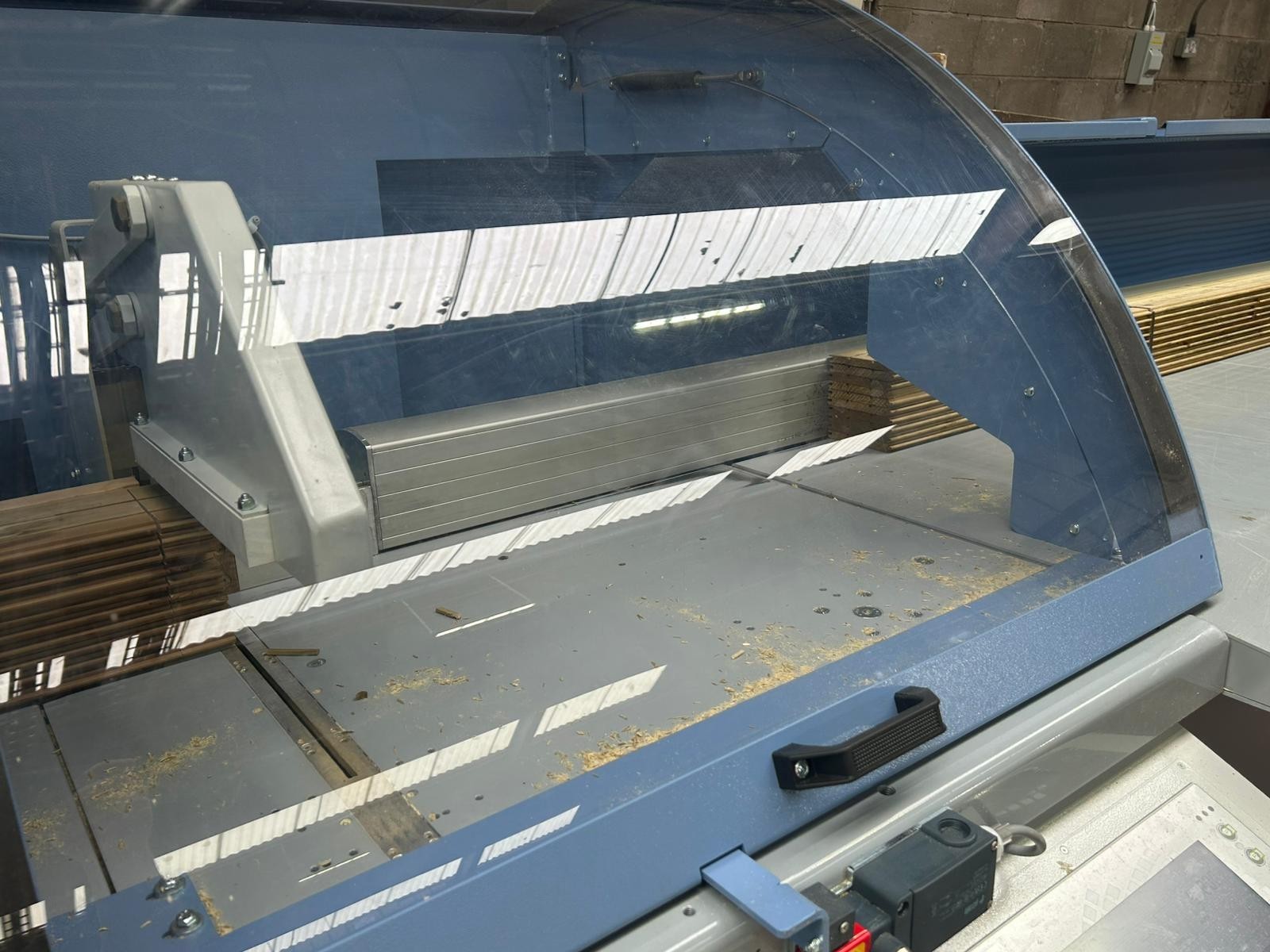

At the core of the Stromab Matrix is the proven TR500 saw unit, a design with more than 50 years of industry application and over 400 installations in the UK. Driven by a powerful 7.5kW motor, the saw is capable of cutting timber up to 135mm in height and 360mm in width, with positioning accuracy of 0.4mm. The rack and pinion feed system allows lengths of up to 14 metres and weights of up to 90 kilograms to be processed without the need for additional rollers.

Control is provided by the colour touchscreen, which allows operators to programme cutting lists using advanced optimisation modes. These include sequencing by length, maximising yield or minimising waste, and defect detection through chalk mark recognition and timber grading.

The decision to install the Stromab Matrix automatic crosscut saw was a natural extension of the long-standing relationship between Rowlinson and JJ Smith. Over many years, Rowlinson has turned to JJ Smith whenever production bottlenecks or machinery challenges arise, relying on their ability to source either standard or bespoke solutions that meet exact requirements.

Charles Firth, Managing Director of Rowlinson Garden Products, explained:

“We’ve worked with JJ Smith for many years, and they are always my first call when we hit a production problem. Their team is a pleasure to deal with and consistently finds the right solution, whether it’s a standard machine or a bespoke setup. One of the most impressive things to me was that, from an initial discussion with JJ Smith on the Monday, the machine had been delivered, installed, and was up and running by the Friday. The Stromab Matrix has been a great addition to our operation, giving us reliability and efficiency exactly when we needed it most.”

Michael Keegan, Sales Engineer at JJ Smith, highlighted the speed with which the solution was delivered:

“When Rowlinson approached us, we understood the urgency of the situation. Having the Stromab Matrix available for immediate delivery meant we could not only resolve their issue quickly but also provide a long-term upgrade. It’s a machine that fits perfectly with their production demands and supports their ongoing growth.”

By working with JJ Smith, Charles was able to avoid production downtime while simultaneously upgrading the cutting process. The Stromab Matrix automatic crosscut saw has provided higher accuracy, faster throughput, and greater flexibility than the previous system, ensuring that production schedules are maintained without compromise. At the same time, its compatibility with advanced optimisation software has given Rowlinson a platform for further efficiency improvements and yield savings in the future.

What began as the search for a temporary second-hand replacement became an opportunity to invest in a long-term productivity upgrade. The Stromab Matrix not only resolved Rowlinson’s immediate production challenge but also positioned them for continued operational efficiency. The case illustrates the importance of trusted supplier relationships in manufacturing, with JJ Smith’s expertise and rapid response once again enabling Rowlinson Garden Products to maintain performance and invest in future-ready technology.