Thorne’s woodworking shop, a symphony of heritage and modernity now boasts over seventy woodworking machines. Recently, they cranked up the buzz by integrating two new game-changing CNC machines, catapulting their production rates for frame components by a staggering 40 per cent.

Rebecca Coleman, Company Director and 4th generation ‘Thorne’, entrusted JJ Smith with finding the machinery solutions to their unique manufacturing challenges – creating bespoke wooden components that aren’t just top notch but cater to the intricate needs of beekeeping spaces.

Rebecca comments “We had contacts at other woodworking machinery manufacturers but didn’t feel they were as progressive as JJ Smith. It also helped that our sales contact Martin Smith has kept bees for over 40 years and was the youngest ever President of the British Beekeepers Association. This helped enormously in that they were interested in getting to know our business and understand our manufacturing processes in order to provide the best solution for our needs, and not push to sell us something that we didn’t need or was over the top for our requirements.”

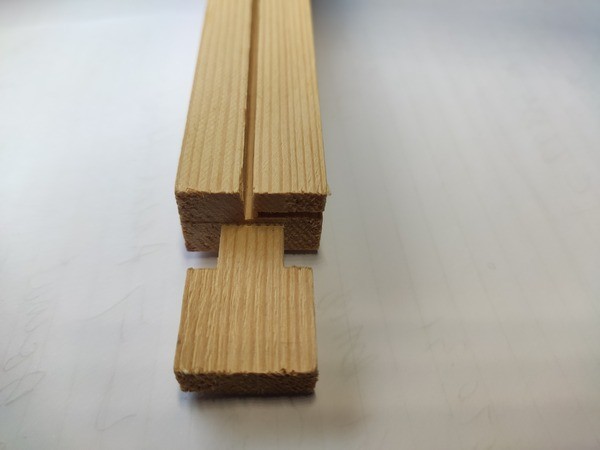

Martin Smith commented, “Having seen the benefits of an investment in a Comec machine for manufacturing ‘side bars’ in 2020, I could see that, whilst the top bar components were considerably more complex, the potential for increased output with reduced labour content was there. Needless to say, UK beehive components are different from those in the rest of the world, and this required a detailed analysis of what are in effect small very high precision furniture components, with machining needing to be carried out of five of the six faces, with the final face having to be sanded. I was able to discuss with Comec, a manufacturer of CNC machinery for the furniture sector, the requirements in detail, to arrive at an appropriate solution for the problem.”

As Thorne commissioned the Comec Frontal CNC through feed machine and Stromab Matrix automatic crosscut saw, the production floodgates opened. Rebecca reflects on the impact –

“Every new machine from JJ Smith feels like a missing puzzle piece found and we ask ourselves how we managed without it. The latest two machines have helped us to increase production by around 40 per cent. Quality and consistency of the components have improved considerably and our processes have been streamlined and adapted to suit the machines, giving even more time savings. They also look great when we are giving our factory tours and are an interesting talking point. The machines are far safer for our operators to run, much quieter and more energy efficient.”

Thorne’s journey doesn’t stop here. With eyes set on the horizon, their next addition to the Lincolnshire workshop will help them to trench and notch component parts for a national beehive. We’re looking forward to collaborating on this exciting project to help Thorne catapult their production even further with cutting-edge CNC woodworking machinery.

For further information and to discuss your requirements, contact a specialist at JJ Smith or call us on 0151 548 9000.