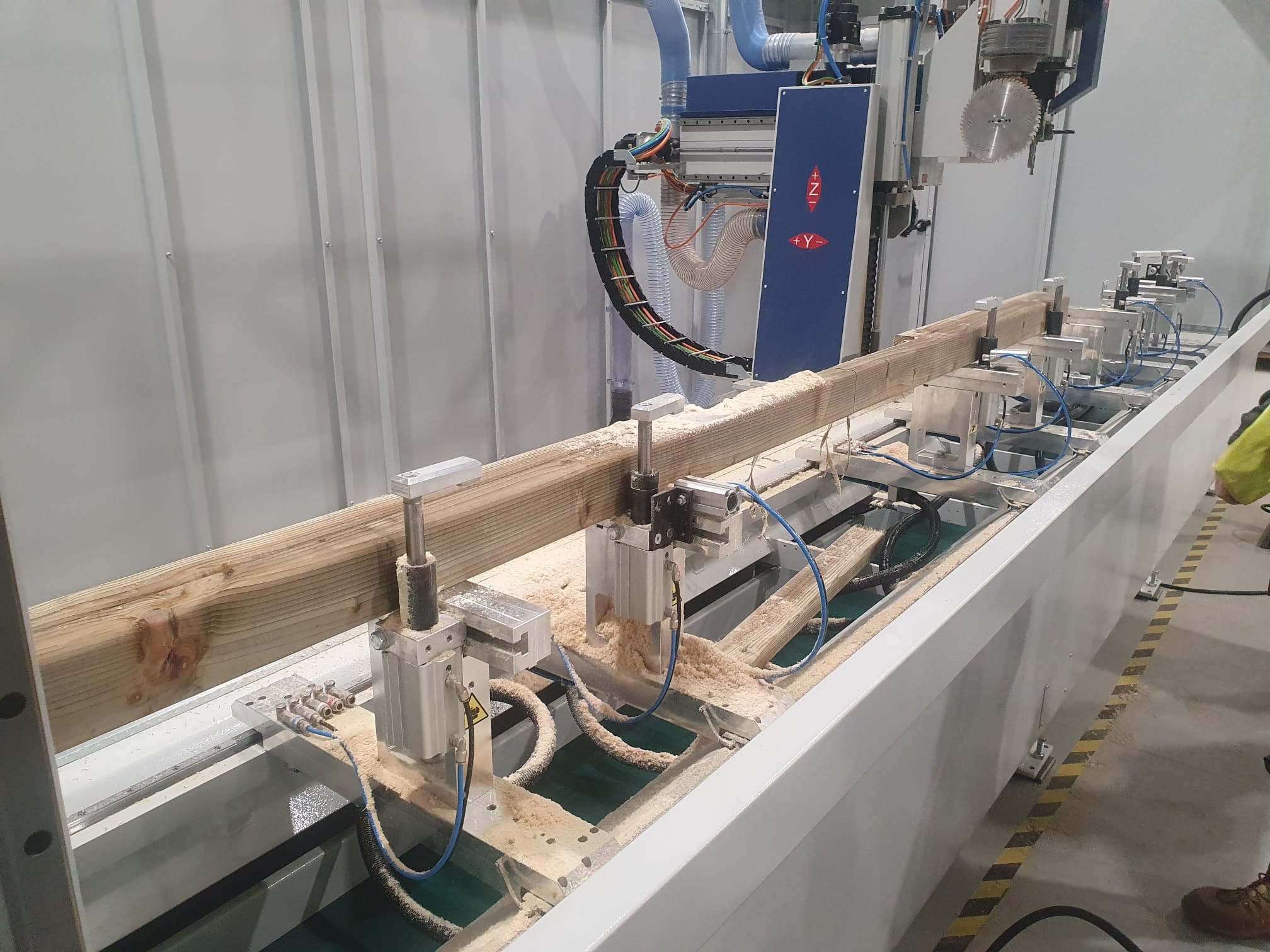

Working out of a modern workshop and offices, Creative Play already have three flatbed CNC routers used for cutting and shaping their panel parts, plus a combination of manual rip saws, crosscut saws and drills for processing solid wood parts that can measure up to 120 x 90mm and up to 4m in length. James was conscious that having so many manual operations was time consuming and unproductive, leading him to look for a CNC machine capable of carrying out all of these different operations, plus even more complex machining that so far, they have been unable to do. Creative Play’s Product Design Manager, Amy Parry, came across JJ Smith's website when researching CNC drilling and shaping machinery and, after reviewing various video clips with James, it became apparent that one of the Comec MD CNCs could well meet their requirements. As a result, they contacted JJ Smith and spoke to Guy Stanley who is the Comec product specialist. A visit to their Liverpool showroom was arranged to see a Comec MD TOP XL 4 axis CNC machining centre in operation. In advance of the visit Amy sent to JJ Smith a selection of part drawings they wanted to see programmed and machined.

Creative Play’s Managing Director, James, comments "As soon as we saw the machine we could see it was a quality piece of kit and extremely well engineered. When we saw it in action we were completely blown away with drilling, cutting (straight or angled) and shaping all carried out on one machine from a single program."

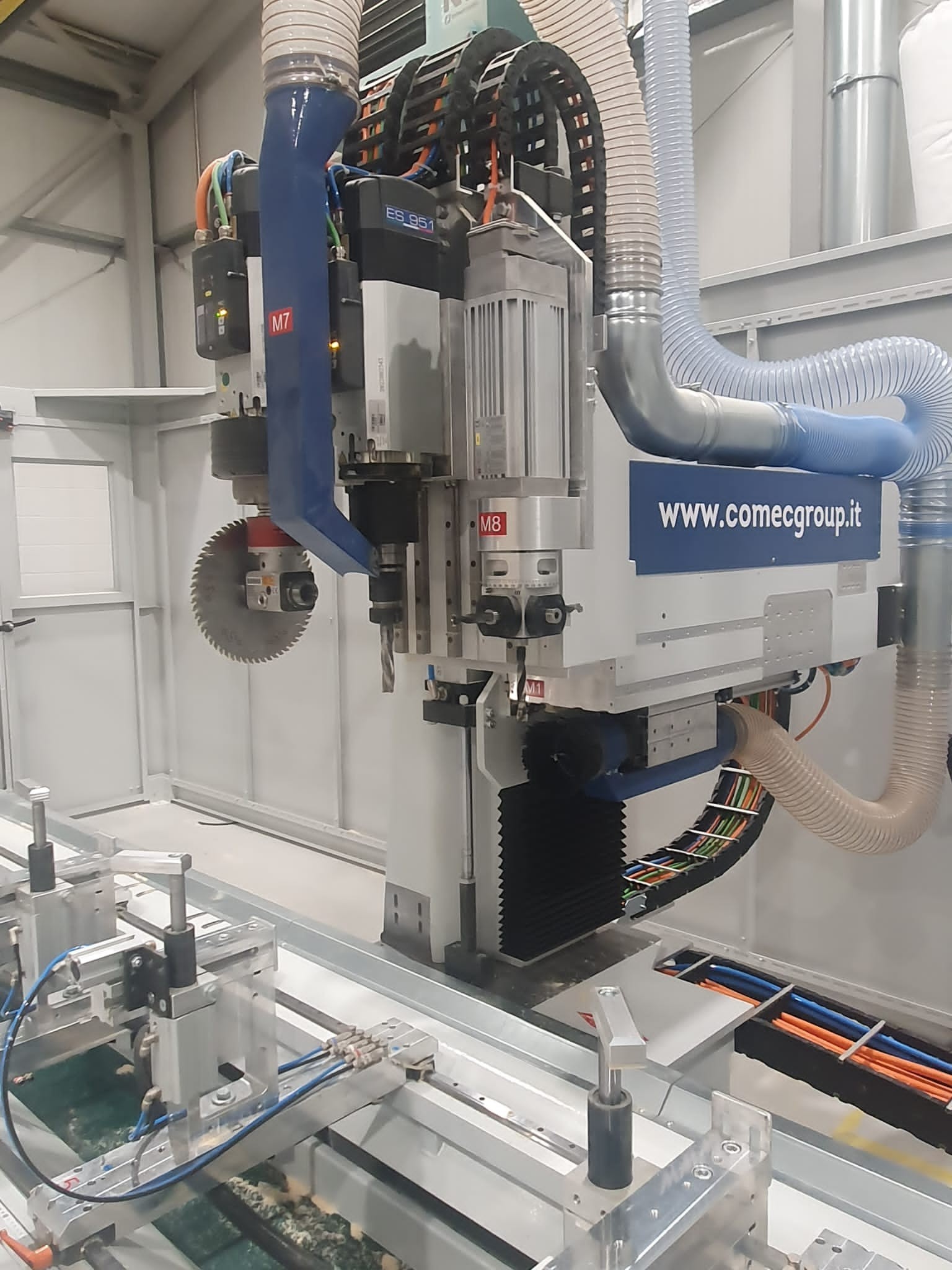

The required machine specification was discussed and agreed on. The model would be an MD TOP XXL with a maximum working length of 4500mm, or two separate working fields each 2000mm working in tandem. The head configuration was 1 x vertical electro spindle working in the C axis, interpolated at 360 degrees, with an aggregate head for sawing or drilling, an additional vertical electro spindle, one horizontal electro spindle plus finally a drill head with five exits giving the ability to drill deep holes on the top, sides and ends. This configuration offers a high level of versatility and productivity.

Following a visit to the Comec factory in Italy for further final testing, an order was confirmed. James comments "Given this was going to be a significant investment for us, I thought it was important to visit the Comec factory to get a better feel of who they are and what they do. To say I was impressed was an understatement. This is serious company making serious machinery. Everything about Comec oozed professionalism, and it was reassuring to know JJ Smith have a very close working relationship which I understand stretches back over 20 years."

The machine was delivered on schedule and commissioned by JJ Smith's own factory trained technicians. Everyone at Creative Play feels the Comec CNC will prove a real 'game changer' not only by giving a significant production boost, but also by having the ability to design and machine parts that previously they could not do. Guy Stanley, Sales Director at JJ Smith, concludes "Working on this project with James and his team has been a pleasure, as they have shown great receptiveness to new ideas and approaches. I am confident that moving forward they will discover more and more things that the machine can do."

For further information or to arrange a demonstration please contact JJ Smith on 0151 548 9000 or email [email protected].